A considerable proportion of sterile products are produced by aseptic processing. Because aseptic processing depends to the exclusion of microorganisms from the method stream as well as avoidance of microorganisms from coming into open containers throughout filling, product bioburden together with microbial bioburden on the manufacturing setting are important aspects referring to the level of sterility assurance of these merchandise.

Smart drawer programs accommodate scientific donor bag and cryo box upright ULT racking, shippable packaging, bottles, and one-use bags and shells

You'll find alternative ways to evaluate and control the microbiological status of controlled environments for aseptic processing. Numerical values included in this chapter are not meant to stand for complete values or requirements, but are informational. Given The variability of microbiological sampling devices and strategies, 1 are not able to moderately suggest which the attainment of such values assures the needed amount of microbial Regulate or that excursions outside of values On this chapter suggest a lack of Manage.

Substitute media to Individuals mentioned may be used delivered that they are validated with the objective intended.

On the simplest amount of design, the HVAC prerequisite for any non-sterile area is to lower airborne particulate by exchanging the air In the room with air that has handed through a filter.

This features using Superior checking systems and info analytics to recognize developments and opportunity difficulties.

Commissioning of the Controlled Setting —Certification by engineering and good quality control which the surroundings has actually been created based on the technical specs of the desired cleanliness course and that, less than ailments prone to be encountered below normal operating disorders (or worst-circumstance disorders), it is actually capable of delivering an aseptic system. Commissioning consists of media-fill runs and effects with the environmental monitoring method.

Controlled places are not only pricey to develop but these are definitely also costlier to maintain. Pursuing factors ought to take into account when designing the click here clean rooms.

It is generally approved by experts that airborne microorganisms in managed environments can affect the microbiological excellent with the intermediate or ultimate goods produced in these locations. Also, it normally is recognized that estimation from the airborne microorganisms is often impacted by instruments and methods used to complete these assays.

Automation is revolutionizing cleanroom sterilization procedures while in the pharmaceutical industry. By reducing human intervention, automation not only minimizes the risk of contamination but in addition enhances process regularity and efficiency.

reveals suggested frequencies of sampling in decreasing order of frequency of sampling As well as in relation for the criticality of the realm with the controlled surroundings becoming sampled.

Reach sustainability and operational ambitions with low Vitality intake, broad temperature selection, and limited chamber uniformity.

The 4000 sequence Regulate amount chamber more info is compatible with just about any size bag, bottle or other storage containers. Contact us for The perfect freeze/thaw orientation for the software.

The selections for sterilisation – Cleanroom Technological innovation – This text critiques various sterilization methods for cleanrooms, like ionising radiation, moist and dry warmth, ethylene oxide fuel, and chemical sterilization, highlighting their apps and Added benefits.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Mara Wilson Then & Now!

Mara Wilson Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Traci Lords Then & Now!

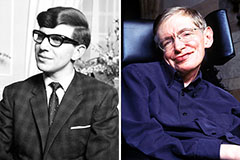

Traci Lords Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!